◆ The forced oil circulation cooling technology widely used at home and abroad for large and medium-sized transformers has extremely low temperature rise (≤ 50 ℃), and the cooling technology is mature, safe and reliable.

◆ The iron core is made of oriented cold-rolled silicon steel sheet with high magnetic conductivity and high saturation magnetic induction strength. The magnetic permeability is much higher than that of ordinary pure iron material, which reduces the hysteresis loss and improves the stability of the total magnetic field.

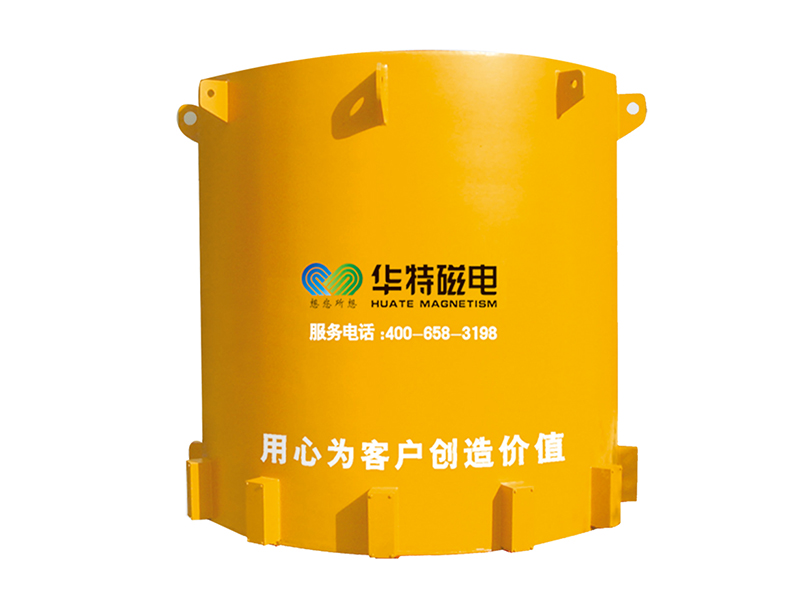

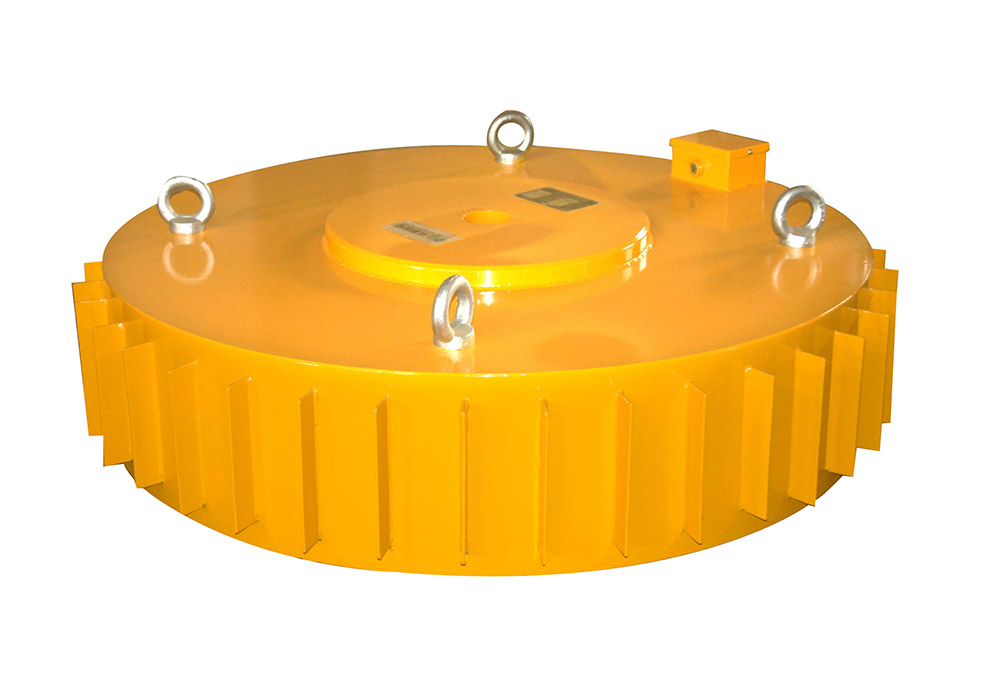

◆ The iron remover has short magnetic circuit, small magnetic loss, large magnetic field gradient, strong iron removal ability and high iron removal rate.

◆ The iron remover is light in weight, compact in structure and heat dissipation * *.

◆ The excitation coil adopts advanced impregnation curing technology, which is completely immersed in the transformer oil. It has excellent moisture-proof, dust-proof and anti-corrosion properties, greatly improving the service life of the coil.

◆ The excitation coil is made of three-dimensional winding, with large heat dissipation area, smooth and reasonable oil circuit, and extremely low temperature rise (≤ 50 ℃).

◆ Automatic iron unloading, simple maintenance, drum shaped drum waist structure, automatic deviation correction function, specially made fully sealed bearing seat, can adapt to the application occasions with large dust on site.