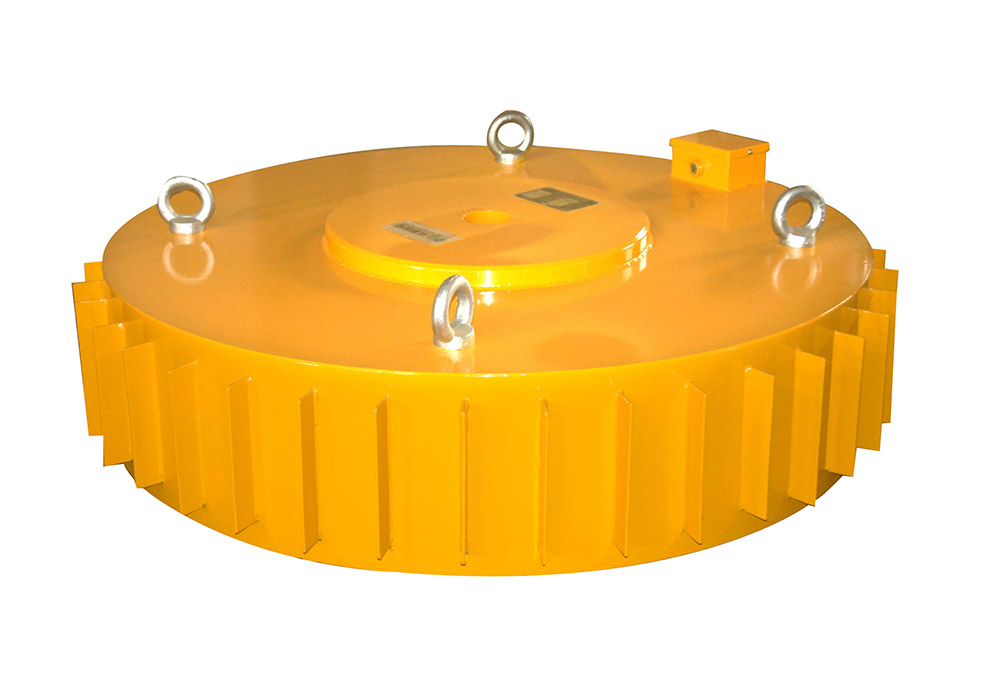

◆ The excitation coil adopts a layered winding structure, which can make the evaporative cooling medium fully contact with the coil and greatly improve the heat dissipation force of the coil.

◆ The working temperature rise of the coil is low, only about 40 ℃, which greatly slows down the aging speed of the coil and improves the service life of the iron remover.

◆ High insulation and proper boiling point cooling medium are used to improve the electrical insulation performance of the coil and ensure safe and reliable operation.

◆ Use the thermodynamic phase change principle to cool the coil, so as to ensure that the operating temperature of the electromagnetic iron remover is low and the temperature distribution is uniform.

◆ The evaporative cooling self circulation system has a good self-adaptive and self regulating ability. The suction difference between cold state and hot state is small, and the temperature does not change with the change of the external environment.

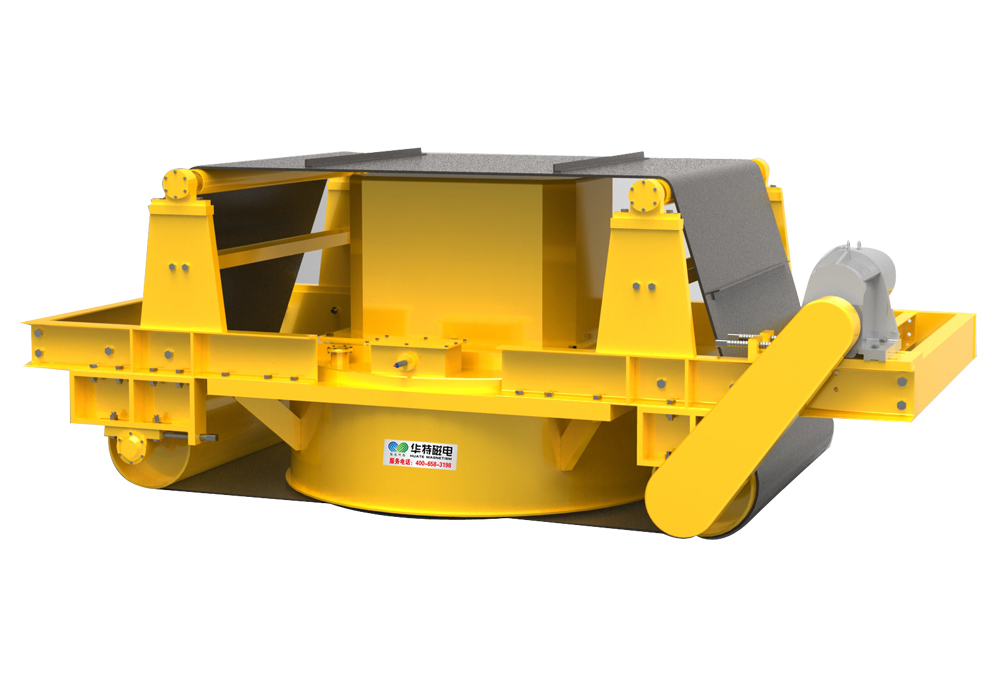

◆ Automatic iron unloading, simple maintenance, drum shaped drum waist structure, belt automatic correction function, specially made fully sealed bearing seat, labyrinth sealing structure, can adapt to the application occasions with large dust on site.